FRPLUS® QY

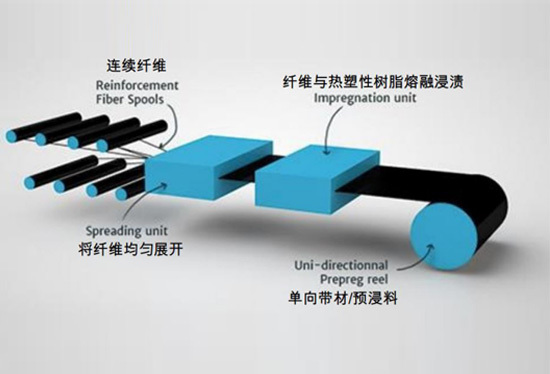

To CFRPLUS®The material is used as a matrix to create one or more 0 °/90 ° bidirectional structures (performance support), and polypropylene (appearance optimization) and non-woven fabric (adhesive surface) are compounded together.

Key words:

thermoplastic composites | Glass

Classification:

Product Catalog

Product Description

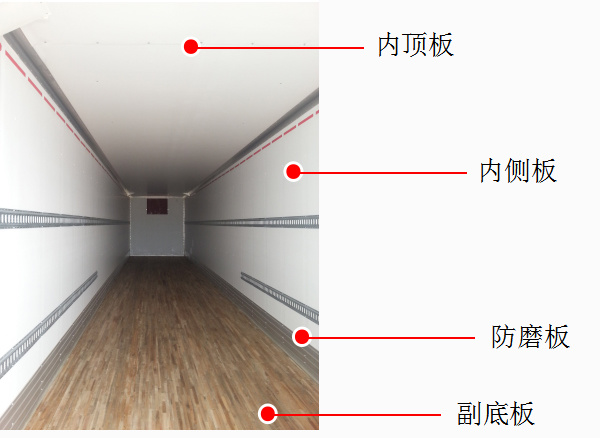

FRPLUS®QY板

The material is used as a matrix to create one or more 0 °/90 ° bidirectional structures (performance support), and polypropylene (appearance optimization) and non-woven fabric (adhesive surface) are compounded together.

The product is light in weight, strong in impact resistance, in line with FDA certification, low thermal conductivity, corrosion resistance, easy to clean and repair.

The "continuous fiber reinforced thermoplastic composite material" independently developed by the company has excellent characteristics such as "light weight, high strength, impact resistance, environmental protection and recyclability". The main performance indicators of the products have reached the international level and can be applied to aerospace, national defense and military industry, etc.

Fiber morphology: continuous-glass fiber, carbon fiber, aramid

Resin category: polypropylene, polyethylene, nylon, polyether ether ketone, etc

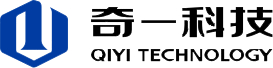

Process characteristics: melt impregnation process; continuous composite process

Main features:

High specific strength and specific stiffness; density <1.5g/cm3

● Environmental protection, recyclable use, easy to clean and repair

● Superior impact resistance and corrosion resistance

Main applications:

● As main bearing structural material, secondary bearing structural material or interior material

● Alternative metal materials, thermosetting composite materials

● Meet the needs of users for light weight, high strength, high impact environmental protection materials

Previous Page

Recommend products

Welcome your message consultation